ROOF PA100 REPAIRS & PROTECTS DELAMINATING SILVER-COATED RESIDENTIAL ROOF

- LOCATION: 3RD ST, BROOKLYN NYC

- DATE APPLIED:

- SUBSTRATE: SILVER COATING

- PRODUCT USED: WBE PRIMER & ROOF PA100

- APPLICATION METHOD: BRUSH & ROLLER

- SITE DESCRIPTION: RESIDENTIAL 1,000 SQFT ROOF

THE CHALLENGE

A 1,000 sqft residential multifamily building coated with a highly reflective silver aluminum coating, exhibited signs of significant deterioration. Years of relentless environmental exposure, solar radiation, fluctuating temperatures, and occasional moisture infiltration, had compromised the coating's functionality and integrity.

The cracked and faded aluminum coating had lost its capacity for effective solar heat reflection. This resulted in increased roof surface temperatures, elevating cooling energy consumption within the building and potentially inducing thermal stress on the underlying membrane. Cracks in the coating provided pathways for water infiltration, threatening the structural integrity of the building and posing a risk of interior damage.

Conventional approaches like patching or recoating with similar aluminum products often offered only temporary solutions. These methods frequently fail to address the underlying causes of cracking and degradation, leaving the roof vulnerable to recurring leaks and premature failure. Additionally, repeated applications of aluminum coatings can contribute to a buildup of layers, increasing roof weight and potentially stressing the underlying structure.

THE SOLUTION

To definitively address these challenges and provide a long-term, high-performance solution, the Armus Roof PA100 system was chosen. This two-step approach effectively tackled both the immediate symptoms and the root causes of the failing aluminum coating.

Water-borne Epoxy Primer: his low-VOC, water-borne formulation penetrated deeply into the cracked surface, filling voids and stabilizing any delaminated areas. The hard epoxy finish created a robust base layer, effectively sealing remaining cracks and enhancing overall adhesion for the topcoat.

Roof PA100 Topcoat: Serving as the final stage of the system's robust defense, this high-performance elastomeric topcoat exhibits exceptional properties for enduring protection. Its fluid application technique allows for seamless conformity to the roof's topography, creating a monolithic barrier against water infiltration. This barrier showcases remarkable resilience through its high elongation at break of 450%, effectively accommodating thermal fluctuations without compromising its integrity. Furthermore, Roof PA100's advanced cool roof technology surpasses the performance of the degraded aluminum coating by employing a more efficient mechanism for reflecting solar heat, thus contributing to lower energy consumption within the building.

IMPLEMENTATION

The application process was simple, and required minimal manpower:

Day 1: Thorough cleaning and debris removal from the roof surface. Strategic application of WBE Primer, focusing on flashing, crack filling and penetration points. The primer was allowed to dry and cure for 24 hours.

Day 2: Application of WBE Primer over the remaining flat roof surface. Application of the Roof PA100 topcoat was applied to previously primed flashing and penetration points.

Day 3: Application of Roof PA100 onto the remaining roof’s primed surface using a roller. Roof PA100 topcoat was allowed to fully dry and cure for 24 hours.

POST-APPLICATION RESULTS & evaluation

The implementation of the Armus Roof PA100 system on the aging aluminum roof yielded demonstrably positive outcomes across multiple key metrics.

Previously vulnerable cracks were effectively sealed, eliminating their role as pathways for water infiltration and securing the building's interior from potential damage. The monolithic barrier created by Roof PA100's seamless application ensures long-term waterproofing, protecting the building's structural integrity and reducing the risk of costly repairs.

Roof PA100's superior reflective properties, exceeding those of the degraded aluminum coating, significantly reduced roof surface temperatures. This translated to decreased energy consumption for cooling within the building, leading to operational cost savings and a positive environmental impact.

The combined strength and flexibility of the Armus system shielded the roof from further deterioration caused by environmental factors like sun exposure and thermal fluctuations. This extended the roof's lifespan, postponing the need for costly replacement and maximizing the return on investment for the building owner.

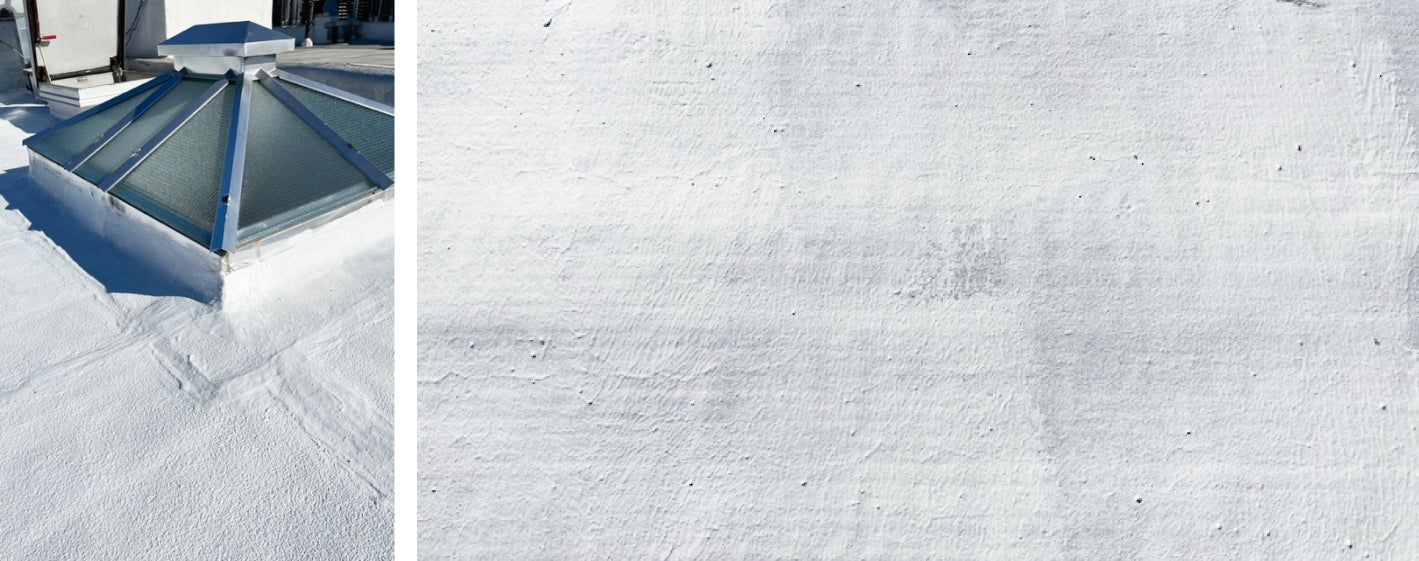

project gallery

Post-cleaning, pre-application of Water-borne Epoxy Primer. Existing worn aluminum coating showing cracks along seams and penetration points.

Application of WBE primer (left). Roof PA100 topcoat spread with roller over remaining primed roof surface (right).

Roof PA100 topcoat. Post-application.

Video

WBE Primer

A TWO-PART WATER-BORNE EPOXY PRIMER THAT CREATES A WATERPROOF BARRIER AND PROVIDES HIGH ABRASION RESISTANCE.

Use with Armus Roof PA100 topcoat.

Roof PA100

A two-part polyaspartic roofing repair topcoat that creates a waterproof barrier, blocks heat transfer and provides thermal insulation.

Use with Armus water-borne epoxy primer.